LEAN Manufacturing

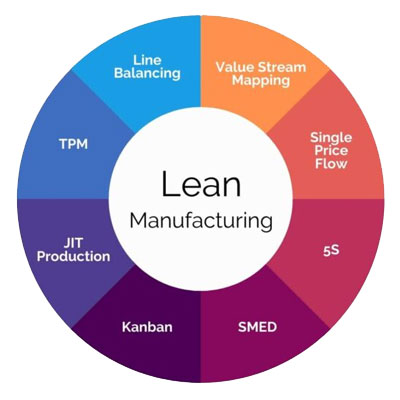

Lean manufacturing is a methodology for eliminating waste and maximizing value in a manufacturing system.

It is a philosophy that focuses on continuous improvement and the creation of a culture where everyone is

empowered to identify and eliminate waste. Lean manufacturing was developed by Toyota in the 1950s and has

since been adopted by many other companies around the world.

The Core Principles of Lean Manufacturing are:

- Identify and eliminate waste: Waste is anything that does not add value to the product or service from the customer’s perspective. There are eight types of waste in lean manufacturing: transportation, inventory, waiting, overproduction, overprocessing, defects, motion, and unused talent.

- Focus on value: Value is what the customer is willing to pay for. Lean manufacturers focus on delivering value to the customer by eliminating waste and improving efficiency.

- Continuously improve: Lean manufacturing is a journey, not a destination. There is always room for improvement, and lean manufacturers are constantly looking for ways to make their processes more efficient and effective.

- Respect for people: People are the key to success in lean manufacturing. Lean manufacturers empower their employees to identify and solve problems, and they provide them with the training and support they need to be successful.