- Company Profile

- Management Systems

- Product Compliance

- Corporate Training

- Gallery

- News & Events

- Contact Us

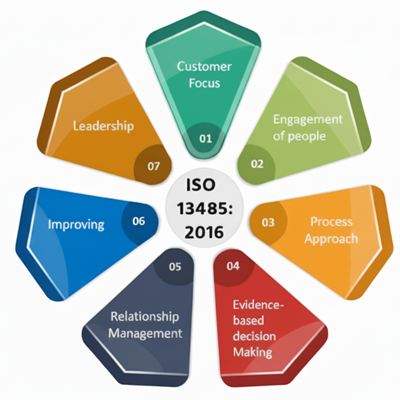

Our Principal Consultant Dr. Abhimanyu Samrat is also Lead Auditor for ISO 13485:2016 Quality Management System for Medical Devices (QMS-MD), where we have vast experience of this type of Management System.

ISO 13485 is a standard that describes the QUALITY MANAGEMENT SYSTEM for design and manufacture of Medical Devices, designed and developed by the International Organization for Standards (ISO). It is mandatory for an organization to effectively implement and maintain the system that adheres to the Standard.

ISO 13485 is considered mandatory even for medical devices that are adhering to Global Harmonization Task Force guidelines. It is also considered to be the initiative for a process to be compliant with European Regulatory requirements.

ISO 13485:2016 specifies requirements for a quality management system where an organization needs to demonstrate its ability to provide medical devices and related services that consistently meet customer and applicable regulatory requirements. Such organizations can be involved in one or more stages of the life-cycle, including design and development, production, storage and distribution, installation, or servicing of a medical device and design and development or provision of associated activities (e.g. technical support). ISO 13485:2016 can also be used by suppliers or external parties that provide product, including quality management system-related services to such organizations.